7 Support

Resources

Competence

Communication

Resources

Resources within

Jemison Metals are allocated based upon the results of the quality

planning and CAPEX processes, which support the quality policy and objectives.

Maintenance of equipment is conducted. These work instructions are

documented and scheduled based on manufacturers’ recommendations and/or JM’s

technical knowledge and experience.

Maintenance activities are performed by qualified personnel.

Assignment of personnel

within Jemison Metals is done on the basis of training, skills, and

experience.

The company has established resources for use of

a multi-disciplinary approach for developing facilities, processes and equipment

plans, including supporting services such as transport, communications, or

information systems. The layout of

the facilities minimizes the travel of material, facilitates synchronous

material flow, and maximizes the use of value-added floor space. Methods are developed for the

evaluation of the effectiveness of existing operations considering overall work

plan, appropriate automation, ergonomics and human factors, operator

productivity, storage and inventory levels.

A multi-disciplinary approach is used for

developing facilities, processes and equipment plans. Plant layouts are reviewed to

encourage efficient use of space, material flow and handling.

All instruments used to measure

mechanical/physical or dimensional features of purchased material,

customer-furnished material or completed product, and processing parameters must

be suitable and accurate to assure credibility of each feature measured.

The Maintenance Department or Head of Quality

is responsible for identifying the type of instrument capable of performing the

required measurement. Accuracy of

each instrument used for final acceptance must be calibrated as required by the

instrument manufacturer or by the instrument history.

Calibration standards are traceable to the

National Institute of Standards & Technology.

The standards used to verify accuracy must be more sensitive than the

instruments being calibrated.

Instruments used for final acceptance features

shall be capable of measurements tighter than the specified tolerance and shall

be used in a manner that ensures that measurement uncertainty is known and is

consistent with the required measurement capability.

Where test software or comparative references are

used, they are checked at prescribed frequencies to ensure they are capable of

verifying the acceptability of product.

When specified by contract, technical data

pertaining to measurement equipment is made available to the customer for

verification that the measurement equipment is functionally adequate.

Instruments found incapable of sustained accuracy

will require shorter calibration periods.

An instrument will be withdrawn from use if it is determined to be

unstable.

The Head of Quality is responsible for

determining the measurements to be made and for identifying the type of

instrument capable of performing the required measurement.

All inspection, measuring and test equipment,

which can affect product quality, is identified in calibration tracking software and calibrated at prescribed intervals against standards,

which are traceable to the National Institute of Standards & Technology (where

no such standards exist, the basis used for calibration is documented in the

calibration software and/or work instruction). The

calibration software details the equipment type, unique identification number,

location, and calibration interval.

The Calibration Software details the check methods, acceptance criteria and

actions to be taken when results are unsatisfactory.

All equipment used for acceptance measurements

are serialized and a certification decal attached, where practical. A calibration record is prepared and

maintained for each such instrument.

The record reflects in-service dates, calibration method and frequency. Accuracy of each instrument used for

final acceptance must be calibrated, as required, by the instrument manufacturer

or by the instrument history.

Suitable environmental

conditions are used for calibrations, inspections, measurements and tests being

carried out.

Inspection, measuring

and test equipment is handled and stored as to maintain accuracy and fitness for

use. Calibrated equipment and calibration standards are safeguarded to prevent

adjustments, which would invalidate the calibration settings.

Data is maintained for calibration control, inspection, measuring and test equipment records IAW QMP 7.5.

Material considered

suspect due to instrument malfunction or calibration integrity is investigated

so as to identify material accepted with the affected instrument. If a determination is made that a

customer may have received suspect material, JM immediately contacts the

customer to determine appropriate measures.

All measuring and test

equipment used to calibrate/test customer products or processing are calibrated

and maintained. Responsibility for

maintaining the calibration system, including records containing as-found

readings and instrument condition, is assigned to the Maintenance Department or

Quality Representative.

Organizational knowledge has many sources at Jemison Metals. Sources include; Individual Experience, External Standards (i.e. ASTM etc), Customer Needs, Technical Expertise, Customer Volume Useage. Organizational is stored with individuals, in proprietary software, and electronically. Organizational knowledge is maintained and made available to the extent necessary either through individual communication or via Jemison's Information Technology systems. When required, Jemison will seek out additional knowledge either through hiring, collaboration or purchase.

Competence, Awareness

Assignment of personnel

within Jemison Metals is performed on the basis of training, skills, and

experience.

We believe we have the

responsibility to continually improve our operation. The improvement of our

processes and thereby our products can only be effectively achieved by

implementing programs to improve the skills and capabilities of our employees. We will ensure that all employees

have the basic skills and understanding of technology necessary to meet the

requirements of their job, consistent with their responsibilities to the

organization.

We further believe that

the training and education process must change and improve on an on-going basis

to meet the challenging conditions of our environment.

The objectives of the program are to ensure that:

Ø

All

employees understand the organization and their role in it.

Ø

All

employees understand our processes.

Ø

All

employees have the basic skills to do their job and function effectively with

the organization.

Ø

All

employees have a sufficient understanding of current and any new technology

associated with their job.

Ø

All

employees understand the relevant need of our customers, our Quality Policy, and

our quality objectives.

Ø

All

employees have the necessary skills to effectively participate in continuous

process improvement programs.

Ø

Employees understand the relevance and importance of their activities.

Employee Training

The foundation of the Jemison Metals

quality program is superior workmanship.

Establishing standards and the subsequent training of our people has been

the key to growth. Customer

satisfaction is a testimonial to the effectiveness of our training program.

The company identifies

the training needs of all personnel performing activities affecting quality, and

provides the required training.

Personnel performing specific tasks are qualified on the basis of appropriate

training, and/or experience, as required.

Performance and Training Records

All employees are

assessed by their supervisors and managers to determine if their qualifications

are adequate or if they need to be supplemented by additional training.

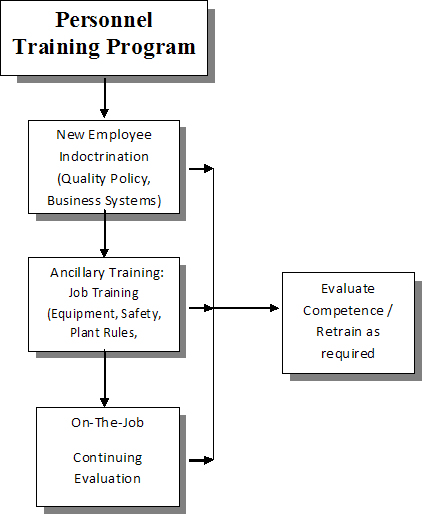

The employee training

is composed of three phases. The

initial or preliminary phase is a formal indoctrination of company QMS, goals,

and business systems (much of which is documented electronically by HR Software). The second

phase is introduction to proper use of equipment.

The third phase is on-the-job training, which includes job specific

ancillary training.

Jemison Metals

maintains records of experience, education, skills, and internal and external

training provided to employees.

Reviews conducted by the employee’s supervisor are used to evaluate the

effectiveness of training and identifies when additional ancillary training may

be required.

Awareness

All employees are trained on the quality policy, what it means relative to their role in the organization, and their relevant quality objectives during the initial hire process. Additionally, it is explained to employees how their work contributes to the effectiveness of the QMS and how nonconforming work can be counterproductive to the QMS.

Communication

Communication within JM is critical to maintaining an effective Quality Management System. Communication between the various levels and functions starts with the Management Review Meetings. At these meetings all aspects of the Quality Management System are discussed with the Top Management Group. The Internal Auditing and Corrective/Preventive Action system are used to collect the information needed to evaluate the effectiveness of the Quality Management System. The Quality Objectives and performance measures are used to track progress and to identify opportunities for improvement. Customer and internal communication is communicated to warehouse personnel to ensure key metrics, customer complaints, and customer returns are disseminated. The frequency of communication, at a minimum, is as follows: Management Review - Annual; Key Metrics - Monthly, Customer Complaints - Monthly, Customer Returns - Monthly. The head of quality has responsibility to disseminate the information to the rest of the organization. Operations Management and/or Local QA disseminates relevant metrics and information to warehouse employees.

Personnel Training

Program Flowchart

Documented Information

This manual contains

references to the Quality Manual Procedures/Process Maps that describe the

processes required to implement the Quality Management System at Jemison

Metals in compliance with the requirements of ISO 9001.

The Quality Management

Procedures, in turn, make reference to other related procedures, work

instructions and flowcharts necessary to describe the sequence and interactive

nature of the processes to ensure conformity to customer specifications and

requirements.

Document Hierarchy

Document Creating and Updating

Documents in the JM Quality Management System that are pertinent to product quality are identified and controlled. All documents and data are reviewed and approved for adequacy by authorized personnel.

“Controlled Documents”

include any means of conveying technical and procedural information wherein the

intended user must be assured of having electronic access to the current

approved version of that information. A master list of controlled documents is

maintained that specifies the latest revision and effective date. Controlled

documents are distributed electronically. Printed versions used for reference,

unless in Controlled Manuals, are considered “Uncontrolled”.

Appropriate documents

are available at locations where operations essential to the effective

functioning of the Quality Management System are performed.

Quality Policy Manual

The Corporate Quality Policy Manual has been prepared to inform employees and customers of the management policies and objectives for the quality of its products and services. The manual is the guide to our quality functions, which are designed to ensure that Jemison Metalss products meet or exceed our customers’ requirements, and the requirements of ISO 9001.

Quality Management Procedures and Process Maps

Work Instructions

These documents address

the “how to” elements of our process

which define in detail those activities controlling or impacting product

quality.

For those applications

that require expanded, detailed, how-to instructions, facility routings and

On-The-Job training provide those details.

These instructions are controlled documents and

are available at the operations they define to ensure conformance with

specifications. Modifications to the

instructions are made whenever changes occur to customer and/or Jemison

Metals standards.

External Documents

JM maintains current

versions of all documents that originate outside of the company that have an

impact on quality. These include but

are not limited to customer, manufacturer, and industry specifications, prints and

standards. External documents that

define customer requirements are obtained or verified as current before an order

is accepted. Electronic customer part specs are stored in BEST & Invex.

JM promptly reviews

all changes to external documents. When these changes necessitate

a change to internal controlled documents, the changes are made and a record is

maintained of those changes.

Document Changes

Document changes are reviewed and authorized by the same authority that issued the original document unless the revised document specifically states otherwise. Revised portions of documents are distributed with a Document Change Request/Notice, and obsolete documents are promptly replaced and identified to ensure against unintended use. Obsolete documents that need to be retained for legal and/or knowledge preservation are appropriately identified.

Record Collection

A control system is maintained for the identification, storage, protection, retention, indexing, access, filing, maintenance and disposition of quality records. Records may be in the form of any type of media, such as hard copy or electronic media.

Quality records are

retained to demonstrate conformance to the specified requirements of ISO 9001

and the effective operation of the Quality Management System. Records are generally collected and

stored by the department generating the record.

This ensures ease of retrieval and verification. Records are cataloged and filed to

facilitate retrieval. Pertinent

quality records from suppliers shall be an element of this data.

Applicable Records

Quality records are

retrievable and traceable to shipped product in order to verify compliance to

customer requirements. Where agreed

contractually, quality records are made available for evaluation by the customer

or the customer’s representative for an agreed period of time. Other quality records are accessible

for verifying the effective operation of the JM Quality Management System,

including but not limited to such areas as supplier quality records, internal

audits, corrective actions, supplier assessments, management reviews,

calibration, training, product review, inspection, testing and product

identification.

Retention, Responsibility and Disposition

The comprehensive listing of required records indicates the following:

Ø Storage location for each

quality record

Ø Retention time for

storage and disposition of each quality record (complies with specific

Ø Responsibility for control of

each stored quality record

Applicable Quality

Management Procedures and Documents:

Ø QMP 7.5 Documented Information

Ø MOP 1 Management Review

Ø SOP 1

Training

Ø SOP 3 Control of Monitoring and Measuring Resources

Revision History

| Date | Section | Description | Revision |

| 9/15/25 | External Docs | Reference to Stelplan updated. | B |

| 11/22/19 | Control Methodology | Updated to reflect GageTrak Calibration Software & Consideration of In-House Calibration Environment as well as reference to HR Software (i.e. Dayforce in Performance & Training Records 2nd Para.) | A |

| 7/20/18 | n/a | n/a | Original |