8 Operation

Operational Planning and Control

Requirements for Products and Services

Design and Development of Products and Services

Control of Externally Provided Processes, Products and Services

Production and Service Provision

Release of Products and Services

Control of Nonconforming Outputs

Identification of Product Requirements

Jemison Metals

reviews customer requirements during award review to make sure that all end

use requirements are met. Some of

the following areas are examined based upon specific product requirements:

Ø

Delivery/post delivery

activities (as appropriate)

Ø

Legal, safety,

environmental, and regulatory issues

Ø

Customer requirements,

including applicable national/international standards

Ø

Packaging and labeling

requirements

Review of Product Requirements

Jemison Metals

conducts a complete review of each new product requirement, including pertinent

documents and quality objectives, during contract review. Some of the following areas are

examined based upon specific product requirements:

Ø

Feasibility and

capability to meet requirements prior to quotation.

Order Processing

Ø

Special characteristics

and/or other requirements are defined.

Ø

Any ambiguous product

requirements are resolved.

Jemison Metals

recognizes the need for continual improvement to provide reliable and accurate

information to control order processing.

We strive to identify and specify such technology during quality

planning.

Records

Customer purchase

requests and other pertinent product documentation are retained as Quality

Records. Verbal orders are identified in Computerized Sales Orders.

Customer Communication

Jemison Metals understands that

communication with its customers is a critical element in understanding and

meeting customer requirements and specifications, including product information.

This is accomplished through customer feedback (including complaints) and

personal contact.

Where product requirements are changed, JM ensures that relevant documents are amended and appropriate personnel are informed.

Applicable Quality

Management Procedures and Documents:

Ø QMP 7.5 Documented Information

Ø

QMP 8.1 Award Review

Ø COP 1 Sales,

Quotation

Ø COP 2 Production

Customer Complaints

A critical element in

JM customer interface relationship is timely response and timely resolution to

customer reported complaints. The

Quality Management System is intended to provide our customers with a tool for

measuring our effectiveness in meeting their requirements.

Our focus is on the

resolution of each problem by initiating a “case”, and as determined by the

Head of Quality, a potential formal corrective action. Corrective Actions identify actions

and time frames for immediate short-term solutions and long-term solutions, and

end with audit verification and validation that ensures a permanent corrective

action. A Customer Complaint Report

is the initial document that provides uniform reporting. Customer information is

retained in information systems software.

Applicable Quality

Management Procedures and Documents:

Ø QMP 7.5 Documented Information

Ø QMP 9.2 Internal Auditing

Ø QMP 8.7 Control of Nonconforming Outputs

Ø QMP 10.2 Nonconformity and Corrective Action

Jemison Metals does not design product. We take existing customer

requirements, through blueprints and/or contracts, and procure the materials, if

not supplied by customer, to produce those requirements.

Jemison Metals

purchase orders specify quantity and quality requirements of our customers or

our QMS. Quality requirements for control items are clearly identified.

All purchased Control

Items will be verified for conformance to the Purchase Order. Purchased Control Items will not be

released for issue until required documentation or test data has been verified. JM will reject purchased items at

any time that evidence is obtained that the item does not conform to specified

quality standards.

Control of Supplier

Jemison Metals

Purchasing is responsible for the selection and qualification of process-related

items and value-added suppliers.

Each supplier must conform to JM’s specific requirements and provide corrective

action when failures occur. Each

of the suppliers must be accountable for demonstrating why problems occur and

how to correct them. Determination of continued approval made at MRB meetings

and/or Head of Quality or Purchasing.

Supplier Performance Analysis

Evaluating and rating of supplier’s performance

in terms of quality and workmanship is the responsibility of Purchasing. Key supplier rating reports (Supplier Scorecards) are

generated, where applicable, and used by JM as an aid in evaluating supplier

performance. Scorecards are disseminated internally to key quality, purchasing & materials management personnel for use (where applicable) in making sourcing decisions.

Documentation and Certification

All items and/or services contracted by JM must

comply with the applicable contractual requirements and identified

specifications on the purchase order.

Unique or objective

documentation requirements, such as qualified personnel or Quality Management

System requirements, are identified on the Purchase Order.

Value-added Services

Outside sources used to

support our processes must be capable of providing the necessary services to

complement our own in-house requirements.

Value-added services must be qualified or available from qualified

sources. These services will be

sample verified upon receipt.

Verification of Purchased Materials and/or Services

Where Jemison

Metals proposes to verify purchased items at the supplier’s premises, Jemison

Metals shall specify verification arrangements and the method of

purchased item release in the purchasing documents.

Where specified in the contract, JM customers

shall be afforded the right to verify at the supplier’s premises and/or JM

premises that the purchased item conforms to the specified requirements.

Receiving

Incoming

product/material received at JM will be inspected for transit damage, quantity,

type, and documentation as specified by the purchase order or the bill of

lading.

Applicable Quality Management Procedures and Documents:

Ø QMP 7.5 Documented Information

Ø SOP 2

Purchasing

Ø QMP 8.7 Control of Nonconforming Output

Ø QMP 8.4 New Supplier Evaluation & Approval

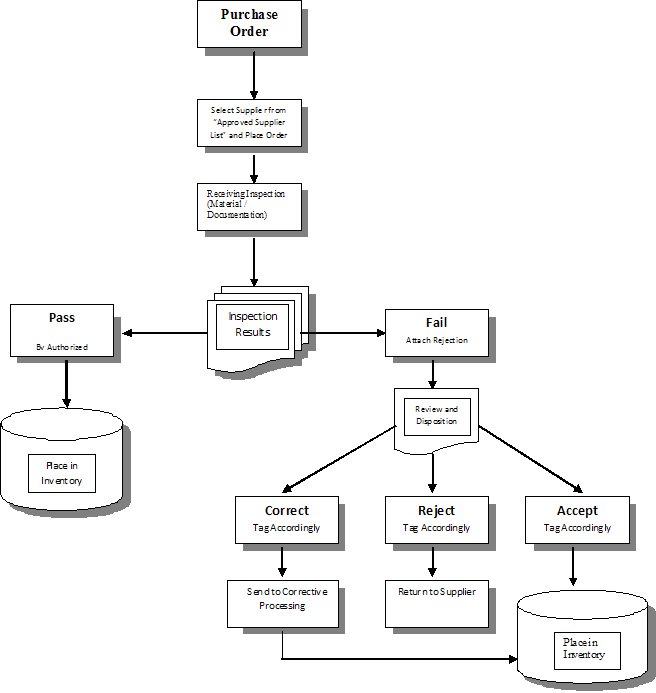

Purchased Material

Flowchart

Production and Service Operations

Processing

The Director of

Operations and facility Plant Managers ensure that all products are processed

under controlled conditions, which include the following:

Ø

Documented procedures

defining the manner of processing when the absence of such procedures could

adversely affect quality

Ø

Use of suitable

processing equipment and a suitable work environment

Ø

Compliance with

reference standards, quality plan and/or documented procedures

Ø

Monitoring and control

of suitable process parameters and process characteristics depicted in a Work

Order, flow chart or Control Plan

Ø

Approval of process and

equipment, as appropriate

Ø

Criteria for

workmanship are specified in the clearest practical manner

Machine operators

verify the set-up for each process ensuring that processing inspection data and

process-monitoring data is collected and recorded and then stored with process

records.

Work Order

A work order is computer generated for each order

number that identifies the sequence of operations and lists pertinent data to

meet customer requirements. The work

order utilizes tag number (as required by the customer) and job number for

traceability and feedback to the system. Operator sign-offs are required at

in-process/final inspection points.

The work order is

generated by Production Planning, prior to running an order. Its purpose is to identify any

processing issues and inspection concerns.

Any routing issues are addressed with changes, if required, before the

job is processed again.

Designation of Key Characteristics

Certain Characteristics of the process are

“critical” to the customer’s successful use of their products and therefore are

given special designation, control and documentation within the processing

system, as required by customer.

Inspection

Inspection points are identified in the work

order. Personnel are required to

verify critical features before an operation can continue.

Change

Significant changes, defined as those changes which could conceivably adversely effect product quality, will be planned in order to evaluate potential unintended consequences and to mitigate any adverse effects.

Applicable Quality Management Procedures and Documents:

Ø QMP 6.3 Planning of Changes

Ø QMP 7.5 Documented Information

Ø COP 2

Production

Servicing & Post-Delivery Activities

Jemison Metals

does not provide after sales service agreements on the products that it sells to

its customers.

Validation of Processes N/A

There are no

“Special Process” performed at

Jemison Metals.

Identification, Traceability, and Status

Purchased material

(product, components, and/or services) is verified for conformance to applicable

standards. Only properly identified

materials are released for issue to processing.

Unused materials are returned to inventory with identification verified

and restored, if applicable.

Product identification

and inspection status of materials are identified using a work order – production

order and/or Tag System that accompanies material through the stages

of processing and indicates the conformance or nonconformance of product with

regard to inspection and tests performed.

A “Reject” tag is attached to material that is nonconforming. Only product that has passed the

required inspections is used.

Product is processed

using a work order – production order and/or Tag System, which includes an

internal lot number (when required by customer), and provides unique

traceability and is maintained through delivery.

Applicable Quality

Management Procedures and Documents:

Ø COP 2

Production

Customer Property

Jemison Metals

shall ensure any customer-supplied property shall be maintained in the same

manner as any other materials within the Quality Management System. Note: customer property can include

intellectual property and personal data.

When customer-supplied

product is received, JM treats it in the same manner as other items that are

purchased. Customer property is

identified as such, and routed through Receiving.

Any deviations are reported to the owner for resolution. Records of such deviations are

retained.

Customer property is

handled and stored in accordance with Jemison’s established practices. When specified in the contract,

unique handling instructions from the customer take precedence. Customer property is identified with

a “C” suffix in Invex.

Applicable Quality Management Procedures and Documents:

Ø QMP 7.5 Documented Information

Ø QMP 8.7 Control of Nonconforming Outputs

Handling, Storage, Packaging, Preservation and Delivery

Methods and means of handling products for processing are used so as to prevent damage and/or deterioration.

Only items that are

properly identified and that have passed the required inspections are authorized

to enter and leave storage areas.

Items are stored in a manner that prevents damage and degradation and are

assessed before use to detect deterioration of items in stock.

Packaging personnel are responsible for:

Ø

Utilizing correct packaging.

Ø

Identifying and labeling, as required,

each shipping coil, pallet or skid.

All packaging shall be performed per customer

requirements.

The shipping clerk is trained and responsible

for:

Ø

Ensuring that all of the items called for on the

shop routing match the items being packaged/shipped.

Ø

Providing sufficient protection for all items

being shipped.

Ø

Ensuring that the correct shipping documentation

is included.

Preservation

Appropriate preservation and segregation methods

are used to protect all items. Items

are protected prior to delivery.

When contractually specified, this protection is extended to include delivery to

destination.

Delivery

The organization will track delivery performance.

Applicable Quality Management

Procedures and Documents:

Ø

COP 2

Production

Revision History

| Date | Section | Description | Revision |

| 9/15/25 | Identification & Handling / Storage / Control of External Provisions... | Updated to reflect new ERP system. | B |

| 11/2/18 | Servicing & Post-Delivery Activities, Purchasing & Supplier Performance | Updated to include Post-Delivery Activities, Added Scorecard language including the internal dissemination and use of Scorecards (where applicable) in making sourcing decisions. | A |

| 7/20/18 | n/a | n/a | Original |